How is 3D printing revolutionizing the manufacture of products and prototypes?

How 3D Printing is Revolutionizing Product and Prototype Manufacturing?: Have you ever thought about how 3D printing can change the product manufacturing? It's not just a tool. It is changing what we know about creating things. Since the 1980s 3D printing has evolved a lot.

Today, she is a major player in the industry. She promises a future full of novelties.

By 2030, around 21.5 million 3D printers will have been sold. Giant companies such as Siemens and Daimler are already using 3D printers. technology. They make advanced parts, such as with Selective Laser Sintering (SLS).

This change is not just for large companies. Small startups can also create prototypes innovative without spending too much.

A 3D printing is used in many places, such as automobiles, medicine and architecture. It is very versatile. With it, we can have tailor-made solutions, changing the way we do things.

They help reduce costs and are good for the environment. 3D printing is changing the way we make things, bringing innovation, efficiency and sustainability.

What is 3D printing?

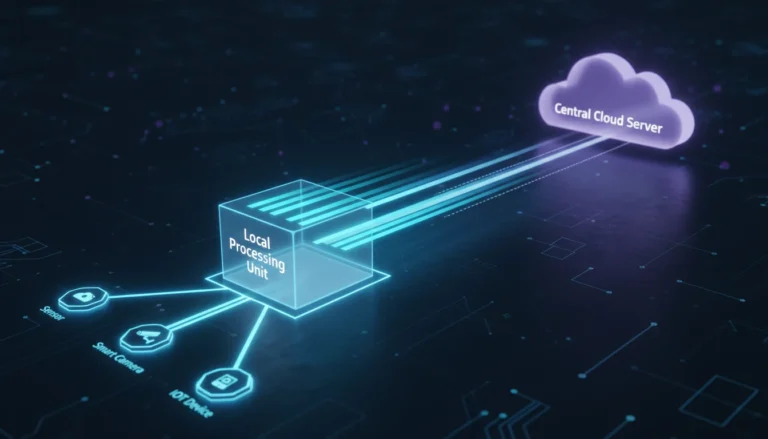

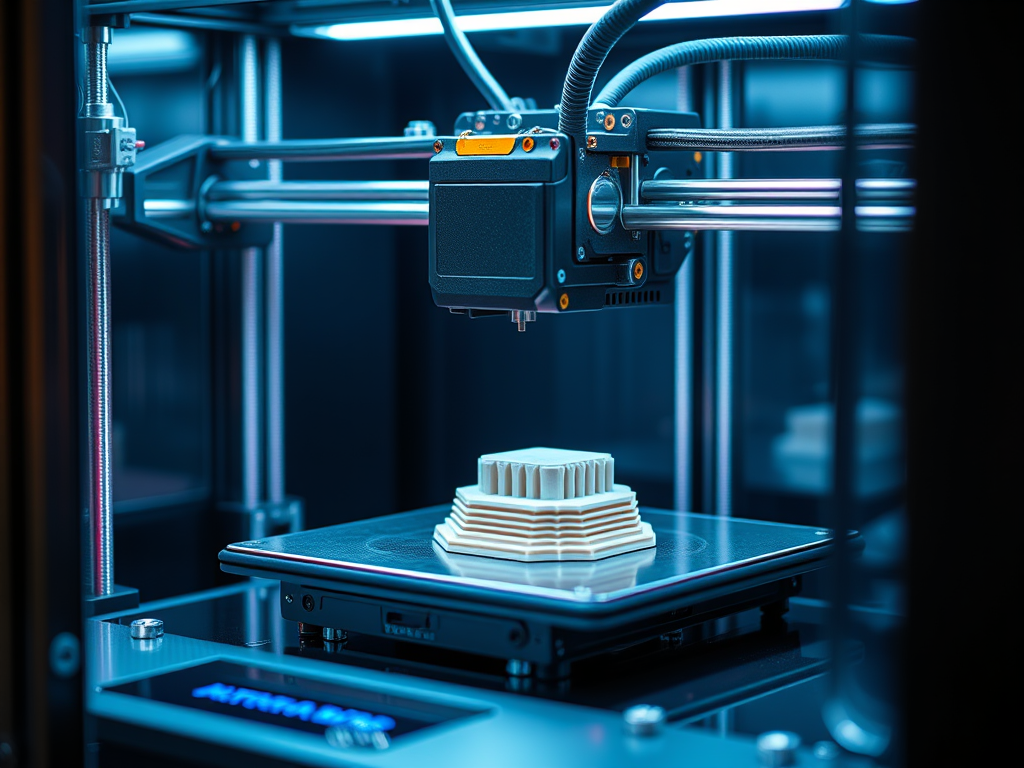

3D printing, or additive manufacturinghas changed the way we create physical objects from virtual models. It adds material layer by layer. This makes it possible to make many types of items, such as spare parts and medical prostheses.

This technology began to be developed in the 1980s. Today, plastics, metals and ceramics are used to create objects.

3D printing stands out for its 3D modeling. It is essential to make prototypes quickly. With it, you can create prototypes in hours or days, saving time and money.

This technique is perfect for complex designs. This is very useful in sectors such as aerospace and automotive, where precision is key.

What's more, 3D modeling helps reduce material waste. This reduces waste and costs. Simulations and virtual tests also help to avoid problems before the actual print.

This technology is versatile and helps in many areas. From medicine to architecture, 3D printing is a great ally.

This versatility creates many opportunities. 3D printing speeds up the development of products and prototypes. If you want to know more about it, get ready for a journey of innovation and efficiency.

History of 3D Printing and its Evolution

A history of 3D printing began in the 80s. This innovation changed the way we make objects. In 1981, Hideo Kodama presented two methods in Japan.

Stereolithography was created in 1984, but was soon abandoned. But in 1986, Charles Hull patented Stereolithography. This led to the creation of 3D Systems, which launched the SLA-1 in 1988.

New techniques such as SLS and FDM have gained prominence. They have helped to evolution of 3D technology.

In the 1990s, 3D printing boomed. Companies such as EOS GmbH and Solidscape appeared. In 1999, medicine was changed with the first printed organic implant.

In the 2000s, 3D printing became more widespread. The RepRap project and bioprinting made it more accessible. In 2010, the Urbee, a printed car, showed the potential of the technology.

Every decade, the history of 3D printing shows great progress. It has become crucial for many industries. It shows how evolution of 3D technology improves our lives.

- The K7 3D Printer is a consumer-grade 3D printer. It comes with its own cutting software which has been specifically mad...

- Suitable for home use education or DIY amateurs, and also suitable for students, children

- It's light, portable for anywhere. And it's silent during work, suitable for indoors and outdoors

How is 3D printing revolutionizing the manufacture of products and prototypes?

3D printing is changing the way we make products. This technology makes it possible to create parts more precisely and quickly. It also helps reduce prototyping time, allowing for more tests and improvements.

Large companies, such as Grendene S/A, are investing in training on 3D printers, such as Formlabs Form 4. This improves productivity and innovation.

Oxford University, for example, is printing functional neurons, showing the potential of 3D printing in areas such as neuroscience.

The partnership between 3DCRIAR and Nissan is an example of innovation. It shows the benefits of 3D printing digital stock. Companies such as Toyota do Brasil, Ambev and Coca-Cola FEMSA are also using 3D printing to save money and speed up production.

3D printing makes it possible to make several parts quickly, saving space. Technology such as SLA and FDM are used in many industries. They make prototyping easier and improve product quality.

| Company | Technology | Benefits |

|---|---|---|

| Grendene S/A | Formlabs Form 4 | Technical training to improve productivity |

| Ambev | 3DCRIBE | Reduced costs and production times |

| Nissan | 3DCRIAR Collaboration | Innovation in additive manufacturing |

| Toyota do Brasil | UltiMaker | Maximizing the benefits of additive manufacturing |

Advantages of 3D Printing in Industry

3D printing brings many advantages of 3D technology for industry. A major advantage is the reducing material waste.

This makes production more sustainable and cheaper. In addition, 3D printing speeds up the creation of prototypes, which can be made in just a few days.

This helps developers to work faster. As a result, new products reach the market more quickly.

Another great advantage is flexibility. 3D printers allow you to make parts on demand. This eliminates the need for large stocks. Thus supply chain optimization The price improves, because the pieces are made on demand.

Small businesses can benefit greatly from this. They can reduce costs and increase efficiency.

3D printing also allows mass customization. This helps to create products that meet specific customer needs.

Customization increases consumer satisfaction, which brings more value to products. This puts companies in a competitive position in the market.

Below is a summary of the main ones advantages of 3D technology:

| Advantages | Description |

|---|---|

| Waste Reduction | Optimized use of materials, reducing costs. |

| Fast production | Development of prototypes in days. |

| Flexibility | Production of parts on demand, avoiding stocks. |

| Customization | Production of articles that meet specific requirements. |

| Design optimization | Facilitates adjustments and improvements to the product during development. |

These characteristics make 3D printing an important ally in industry. It helps companies innovate and become more efficient. This is essential in a competitive market.

- [ Resume printing function ] - The Ender 3 has the ability to resume printing even after a power outage...

- [ Easy and quick to assemble ] - Comes with several assembled parts, you only need about 2 hours to assemble 20 percent...

- [ Advanced Extruder Technology ] - Upgraded extruder greatly reduces the risk of clogging and poor extrusion; The...

3D Printing Processes and Techniques

The 3D printing processes have changed the way we do things. They offer several different methods.

FDM (Fused Deposition Modeling) is widely used because it is quick and easy. It helps to create prototypes quickly, improving the quality of products.

SLA (Stereolithography) is great for fine details. It uses liquid resins and lasers to create high-quality parts. SLS (Selective Laser Sintering) is good for complex, durable parts.

The 3D printing processes have also changed the way we create products. Now, ordinary people can design. This has helped small businesses and designers to create more without spending too much.

| Method | Materials used | Benefits | Limitations |

|---|---|---|---|

| FDM | Thermoplastics (PLA, ABS) | Affordable cost and ease of use | Bottom surface finish |

| SLA | Liquid resins | High precision and detail | Higher cost and curing time |

| SLS | Dust (plastic, metal) | Structural puzzle and resistance | Expensive equipment and long printing times |

3D printing techniques and creativity are bringing innovations to many sectors. Fashion and engineering are among the most benefited. 3D printing also helps the environment by using recyclable and sustainable materials.

Rapid and Iterative Prototyping

A rapid prototyping is a major innovation in 3D printing. It allows prototypes to be created in hours, not weeks or months. This makes product development much faster.

Companies like Fiat and Nike use 3D printing to improve design. They can quickly change their ideas according to what the market wants. This makes development faster and more effective.

3D printing also helps save money. You don't have to spend on tools and molds to make prototypes. This reduces initial costs and allows you to make more personalized products for your customers.

What's more, 3D printing can create complex parts. This greatly helps sectors such as automobiles and aerospace. It allows for constant innovation and testing of new designs and materials.

| Benefits of Rapid Prototyping | Description |

|---|---|

| Agility | Production of prototypes in hours, allowing adjustments to be made in real time. |

| Cost reduction | Eliminates the need for molds, reducing production costs. |

| Customization | Facilitates product customization according to customer demands. |

| Innovation | It allows continuous experimentation with new designs and materials. |

| Local Production | Reduces dependence on long supply chains. |

The impact of 3D printing in rapid prototyping is changing product development. It improves every step of the process.

Mass Production: The New Reality

A industrial 3D printing is changing what we know about mass production. It started out making prototypes, but now it allows you to make several parts at the same time.

This is very important for sectors such as automobiles and aerospace, where quality is essential.

Just like iPhone has changed computing, 3D printing could change manufacturing. Companies like Nike are using this technology to make personalized products. This changes how brands connect with their customers.

3D printing also helps to reduce waste. It allows products to be made only when they are ordered, which reduces the need for large stocks. This changes logistics and helps make companies more sustainable.

Companies that use 3D printing are quicker to change to what the market wants. This agility gives them a competitive edge. It also helps create a future where everything is personalized and innovative.

Mass customization through 3D printing

3D printing is changing the way we produce things. It is now possible to make unique products for each customer. This improves the consumer experience and helps strengthen brand loyalty.

With 3D printing, it's possible to make many personalized products. For example, Adidas makes shoe soles that meet the needs of athletes.

Align Technology also uses this technology to make Invisalign dental aligners, offering a more effective treatment.

There are many materials to use in 3D printing, such as plastics, metals and resins. This makes it possible to create both aesthetic and functional items. Plastics such as PLA and ABS, and metals such as stainless steel and aluminum, are some examples.

Advances in additive printing processes have greatly improved the mass customization. Companies like Erpro 3D Factory show that it is possible to make millions of parts quickly.

For example, Chanel produced millions of Volume Révolution mascara brushes.

With 3D printing, quantity and customization are guaranteed. This is not just a trend, but a new level in manufacturing. You can have tailor-made products with a unique design.

| Product | Company | Objective |

|---|---|---|

| Shoe soles | Adidas | Improving performance and comfort |

| Dental aligners | Align Technology | Personalized dental care |

| Make-up items | Chanel | Produce items with a distinctive design |

Impact of 3D Printing on Sustainability

3D printing helps a lot in sustainability. It reduces material waste in manufacturing. This is because it only uses what is necessary, which is very efficient.

It also allows plastics to be recycled. This is done through grinding, filtration, extrusion and chemical recycling. It thus transforms waste into new materials, helping the circular economy.

The use of biodegradable materials, such as PLA, is another strong point. This plastic is biodegradable, which is much better than ordinary plastics that pollute for years.

However, there are still challenges. The price of 3D printers is high for many. But over time, it's getting cheaper, allowing more people to use them.

See the table below to better understand the comparison between traditional methods and 3D printing in the sustainability:

| Metrica | Traditional methods | 3D printing |

|---|---|---|

| Material waste (%) | 30% to 50% | 5% to 10% |

| Recyclability | Low | High |

| Pollutant emissions | High | Reduced |

| Production time | Long | Quickly |

O environmental impact of 3D printing is big. It's changing the way we do things, like healthconsumer goods and automobiles. With the growth of 3D printing, we will produce in a more conscious and sustainable way.

3D Industry Trends

3D printing is changing the way we make things. The 3D industry trends show a world in constant change.

A Artificial Intelligence is bringing new ideas to design, making everything more creative and efficient.

With the arrival of cheaper printers, small and medium-sized businesses can use this technology. This opens the door to innovation in many sectors.

Prints are being used in new areas such as medicine and construction. They help create personalized materials and complex structures. This is changing the way we tackle health problems and urbanization.

The global 3D printing market grew to US$ 12.6 billion in 2020. And it is forecast to grow by 17% per year until 2023. By 2026, the market could reach US$ 37.2 billion.

By 2028, the market could grow even more, reaching US$ 62.79 billion. This shows the great potential of 3D printing.

In the metals industry, 3D printing is growing very fast. Companies like General Electric are leading this change. They are using 3D printing to improve processes and reduce costs.

| Company | Revenue (US$) |

|---|---|

| Autodesk | 1.06 billion |

| Raytheon Technologies | 15.88 billion |

| Ansys | 452.55 million |

| HP Inc. | 15.29 billion |

| Desktop Metal, Inc. | 18.98 million |

These projections show that 3D printing is essential for the future of manufacturing. Printing technologies are improving, enabling uses in many sectors. Investment in research promises to bring even more innovations.

Conclusion

3D printing is changing the way we make products and prototypes. From the innovation of Stereolithography (SLA) to Fused Deposition Modeling (FDM), every advance has been important.

New materials and better precision and speed have made a big difference.

With the advance of 3D printing, personalization and sustainability are becoming stronger. Medicine and the automotive industry are already seeing the benefits.

The technology makes it possible to create items on demand and customized pieces, showing its versatility.

What's next? O the future of 3D printing promises more innovations. New materials and methods will expand its applications. 3D printing is transforming industry in real and significant ways.

FAQ

Q: What is 3D printing?

A: 3D printing creates physical objects from digital models. It adds material layer by layer. This technology is used in various sectors, making product manufacturing faster and more efficiently.

Q: What are the main advantages of 3D printing?

A: The advantages include less material waste and the creation of complex objects with ease. It is also quick to create prototypes and allows you to mass customization.

Q: How does 3D printing help with rapid prototyping?

A: It allows designers to create prototypes in hours, not weeks or months. This makes it easier to make adjustments and improvements in real time.

Q: What are the most common 3D printing processes?

A: The most common processes are FDM, SLA and SLS. Each has its own applications, depending on the needs of the project.

Q: Can 3D printing be used for mass production?

A: Yes, it's used for mass production Today. Large, precise printers allow several parts to be manufactured at the same time.

Q: How does 3D printing contribute to sustainability?

A: It reduces material waste and allows local production. This reduces the need for transportation. The adoption of recyclable materials and bioplastics also improves its environmental viability.

Q: What are the current trends in 3D printing?

A: Trends include the use of Artificial Intelligence in design and the growth of affordable printers. 3D printing is also being used in new areas such as medicine and construction.